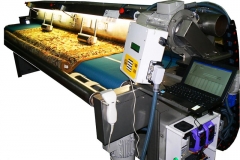

Catinet automatic rug and carpet finishing and packaging machines were designed to facilitate the latest, an extremely important function in the process of cleaning carpets, because affecting the final appearance of the cleaned carpet.

With Catinet automatic rug and carpet finishing and packaging machine the following activities, carried out on the small area, become extremely easy: final brushing, gluing the edges, vacuuming, measuring, cutting carpet, carried.

Rotating brush and a powerful vacuum system raise the pile of the carpet as well as comb fringes to have them properly laid before the carpet will be rolled up and packed. Rotating brush, placed along the top of the table, automatically adjusts to the thickness of the carpet. The belt is moving carpet during processing and ultimately collapses carpet in preparation for packaging.

Additional function (option): automatic carpet measuring

On the customer request, it is possible to assemble on a carpet finishing machine additional function – carpet measuring and registration. It allows:

- to register a carpet in a computer system (dimensions, registration number, carpet’s type, spot type, customer data, operator’s ID number)

- to print a label with data about carpet,

- to issue an invoice.

Features:

- Free-standing. On customer request, possibility to install a devise on the wheels. Free of charge.

- Possibility to install a machine directly at the wall,

- Material – stainless steel,

- Start up with a single push of the button

- Combing fringes function,

- Automatic adjustment of the brush to the thickness of the carpet,

- High power extraction of 2 vacuums provides high quality finish carpet

- High power used Extraction (two) provides high quality finish carpet,

- Carpet combing, rolling up, packaging and measuring on the surface less than 4m2,

- Included with the device – arm with foil film designed for carpet packaging together with foil cutting tool.

Required installations:

- Electricity

- Pressed air